Machining

We at Teems strive to deliver consistently top-quality products and service for our customers. Below is a list of the precision machining equipment we use.

Haas DS30 3” thru spindle with bar feeder

Haas TM2 - Toolroom mill

Haas TL3 - 3.5” thru spindle lathe

Haas VF3 - Vertical mill

2 = Haas VF6-SS - Vertical mills (Pictured above)

Doosan Mill DNM 5700

2 = Okuma Lathe LB4000 EX II

Okuma Mill M5660V

Welding

We here at Teems Fabrication weld a variety of materials including Carbon, Stainless, Aluminum, and specialty steel materials. We have the ability to weld with TIG, MIG, Stick, Resistance, and Robotic welding. We will weld everything from light gauge to heavy plate.

No results found

Forming

Our Forming department is fully equipped with the right machines to meet all of our customers requirements. Below is a list of our machines.

2 = Diamond BH - 13530 135 ton with a 122” bed length

AccuPress Edge 250 ton with a 144” bed length

AccuPress AdvantaF 60 ton with a 72 in bed length

Lemas TR 180/6 with a 7.08in diameter that can roll 1/4in material the full 6ft bed length (Pictured above)

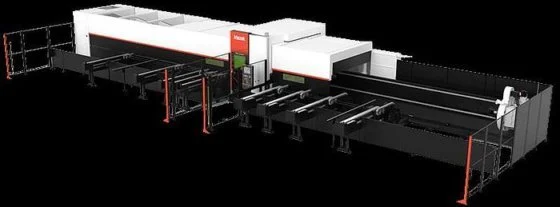

Cutting

Our Flow Waterjet is capable of cutting most materials that are 6 inches or less, including metals, plastics, stone (manufactured and natural), glass, foam, and ceramics. Because there is no heat and no work induced stress incurred in the cutting process, almost any material is suitable for cutting leaving a clean edge. Our Waterjet has a 5ft x 10ft bed.

Machitech Diamond Cut Highdef Plasma table, with Hypertherm XPR300. Cutting bed is 72” x 144”, with cutting capacity of 2” steel.

Our Mitsubishi 40CFX Watt Laser and Mazak Optiplex 3015 NEO 20 KiloWatt laser are powerful resonators and come equipped with fully automated loading and unloading systems. Their exceptional beam quality and stability deliver maximum cutting power, while the advanced beam delivery ensures superior edge quality, consistent processing, and reliable repeatability across a wide range of materials.

Our Mazak FG400 Tube Laser, a 3D high-speed energy efficient fiber laser processing machine for continuous automatic cutting complex shapes, coping and machining of pipe, tube and structural materials.

The HYD-MECH S-20A is a fully automatic bandsaw with a 13”x18” rectangular capacity and a 13” diameter round capacity. It is equipped with a bundle vise/index clamping to cut multiple quantities at the same time. Automatic indexing can control cutting length accuracy to +/- .005”. The head can swing from 90-40 degrees. The variable speed blade drive cuts between 75 and 400 surface feet per minute.

Powder coating and Assembly

Here at Teems we are equipped with a Batch Powder Coat System that has a 10ft x 10ft x 25ft booth pairing with a 10ft x 10ft x 25ft oven. All of our parts are chemically cleaned before we begin our powder coating process. This building sits outside the main building and is also the area our assemblers work in to build any product according to the blueprints we are provided with. Lastly in this department we have BB2000XLD-BVD sandblaster.

Shipping and Receiving

The shipping department handles customer pick up and delivers products.

We also have Freight options and more advanced shipping methods that can provide deliveries across the Globe.

We palletize based upon the part requirement and size Ex: Loose, Boxed, Wrapped, or Banded.

We here at Teems Fabrication are always striving to exceed customer requirements and our shipping department is no different if you need something

special or specific for the part we are shipping you then we will meet those requirements.